Vertical Line Rail Machining Center; SD-V1170

1、 List of Main Machine Configuration (Unit: mm)

Regulations; Grid; Speak; bright

quantity

Origin

Mitsubishi System (M80)

full set

Japan

Use Taiwan Shangyin/Intime for XYZ axis; Precision Ball Linear Guide (XYZ45)

full set

Taiwan

Use Taiwan Shangyin/Intime for XYZ axis; Precision grinding ball screw (XYZ4012)

full set

Taiwan

Taiwan Ruiying Direct Connection Short Nose Spindle BT40/150/12000rpm

1 unit

Taiwan

24 bit disc cutter library (Yitai)

1 set

Taiwan

Z-axis counterweight selection: nitrogen counterweight

1 set

Dongguan

Cast iron bed body (HT300)

1 set

self-control

Cast iron mechanical parts (HT300)

1 batch

self-control

Distribution cabinet constant temperature air conditioning system (Red)

1 set

Dongguan

Schneider Electrical Accessories (Schneider)

1 batch

Tianjin

Pneumatic components (Yadeke)

1 batch

Taiwan

Imported SKF (SKF) bearings from Sweden

full set

Japan

Spindle water cooler (Reid)

1 unit

Dongguan

Electronic handwheel (Dongce)

1 set

Guangzhou

Knife alignment instrument

1 unit

self-control

XYZ axis with expandable steel plate cover

1 set each

self-control

X/Y/Z axis plastic drag chain (Dingtai)

1 set each

Dongguan

Automatic lubrication oil pump (Proton)

1 set

Dongguan

Air filter (Japanese Lehman M107-A air filter)

2 sets

Zhejiang

Water spray device

2 sets

self-control

Water pump 750W

1 set

Changzhou

Machine tool accessories

1 set

Shenzhen

BT40 Knife Handle/Complete Set of Reduced Nipple (Three in One)

5

Shenzhen

Chain plate slag discharge machine (optional)

nothing

self-control

Four axis turntable (optional)

nothing

Taiwan

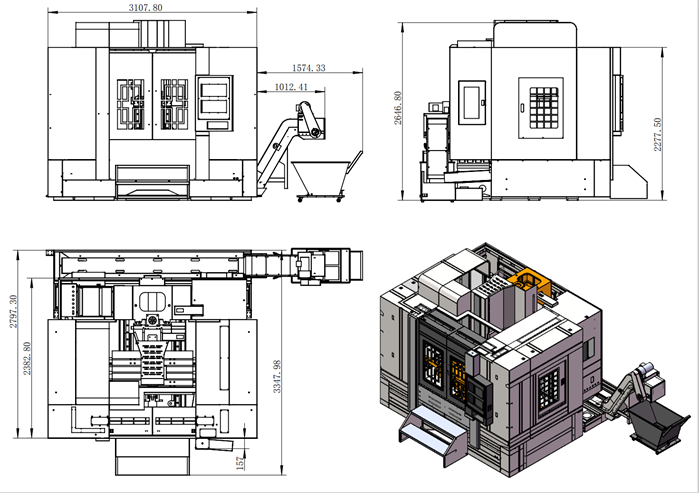

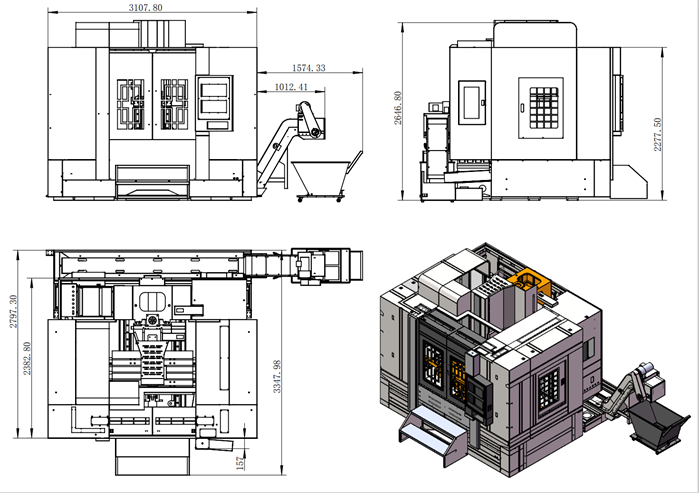

2、 Technical specification parameter table: (unit: mm)

model

SD-V1170

Workbench size

1200 * 650; (T-shaped groove 18 * 5 * 100)

Spindle nose end to workbench

Maximum 850 to minimum 150

X-axis travel

one thousand and one hundred

Travel Y-axis

seven hundred

Z-axis travel

seven hundred

X/Y/Z fastest movement speed

X36 meters/minute

Y36 meters/minute

Z36 meters/minute

Maximum processing speed

12 meters per minute

servo system

AC servo

System resolution

zero point zero zero one

Three axis verticality

0.015mm

Whole machine positioning accuracy

&Plusmn; 0.01mm

Localization accuracy

Within 300± 0.008mm

Repetitive positioning accuracy

0.005mm

Number of spindles

1 unit

Spindle servo power

11KW

Spindle servo torque

52.5Nm

Spindle speed

12000 rpm/min

Disk cutter magazine

24 bit

Knife changing method

automatic

Clamping tool handle

BT40

Knife alignment method

automatic

The countertop bears a load

800Kg

Rated voltage

380V/50HZ

Maximum power of the entire machine

18KW

Overall weight

About 4300Kg

External dimensions (length * width * height)

Approximately 3150 * 2650 * 2600

3、 Standard configuration and accessories for the host:

one

Controller

eleven

1 mechanical, electrical, and operation manual

two

Directly connected spindle BT40-150-12000

twelve

Rigid tapping function

three

Automatic lubrication system

thirteen

Electrical box air conditioning

four

Adjustable foundation cushion block

fourteen

Operation Manual, Program Manual, and User Manual

five

Toolbox

fifteen

5 BT40 blade heads (including rivets and wrenches)

six

Work lights

sixteen

BT40 locking tool holder

seven

Warning lights

seventeen

&Nbsp; M16 Ma Tie

eight

Spindle blowing device

eighteen

One 6-inch screwdriver

nine

transmission line

nineteen

Lock Mouth; ER32 (4-20) 1 set

ten

Fully enclosed cover

twenty

Shield

4、 Machine environment and hardware facility requirements;

Number

Environmental projects

Project Requirements Standards

one

Power requirements

AC380V (4P) 50-60Hz, air switch 100A, power supply voltage fluctuation range 380V± Within 10%

two

air compressor

Using screw compressor, air storage tank, three-stage filtration,≥ 0.55Mpa, flow rate≥ 100L/min

three

Vacuum pressure

&Ge; 0.6 MPa

four

Air dryer

Must have an air dryer with automatic drainage function

five

Environmental noise/vibration

&Le; 75dba

six

Ground requirements

The ground is required to be flat, stable, and the difference between the highest and lowest points should not exceed 5mm

seven

Environmental humidity

Suggest 45% -65%

eight

Gas moisture content

No moisture