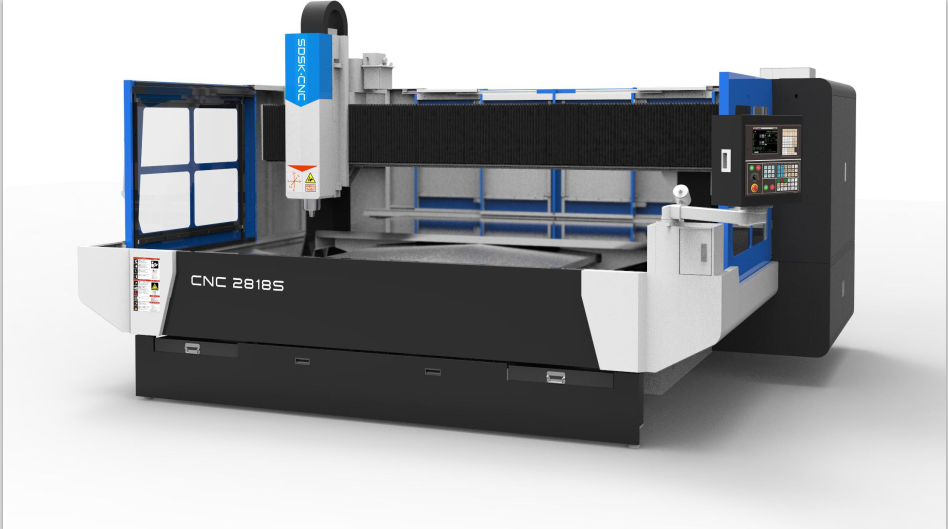

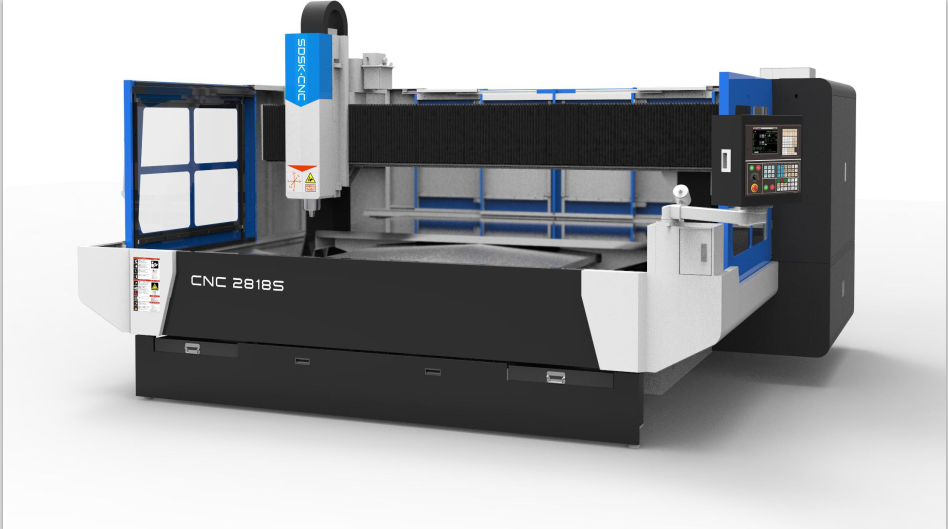

Machine Introduction:

The SDSK2818S model is a large glass carving machine specially designed for doors for customers; The motion mode is to move the Y-axis workbench forward and backward, the X-axis spindle moves left and right, and the Z-axis spindle moves up and down. The body adopts top-notch Jinan granite (marble) structure, which never deforms; The three-axis adopts imported Taiwan Shangyin/PMI precision grade linear guide rail, grinding grade ball screw, precision grade coupling, Weizhi/Yaskawa/Huichuan/Panasonic servo motor, distribution cabinet constant temperature system, advanced spindle refrigeration system, automatic lubrication system, coolant multi-point water spray system, and air filtration device, ensuring higher processing accuracy, speed, and stability; Specially suitable for precision punching, edge grinding, chamfering, and irregular processing of capacitive screen glass panels, various large-sized glass panels, etc< Br/>

Attachment: Can be connected to automatic loading and unloading mechanisms< Br/>

&Nbsp< Br/>

&Nbsp;

Preface

Number

Specification Description

quantity

one

Outer cover: 2mm steel plate, baked paint (stainless steel water tank)

1 set

two

Aluminum workbench size: 2800 in X direction, 1800 in Y direction, thickness 50

1 set

three

Marble body, marble crossbeam

1 set

four

XYZ axis uses Yaskawa/Huichuan/Panasonic servo motors (optional)

4 sets

five

XYZ Axis; THK/Shangyin or Intime/THK precision linear guide rail (optional)

8 sets

six

Use for XYZ axis; Shangyin or Yintai precision ball screw

4 sets

seven

Deep carving CNC system/Weihong/New generation (optional)

1 set

eight

inverter

1 set

nine

Schneider Electric Accessories

1 batch

ten

Electric spindle 30000rpm, 7.5KW, pneumatic tool change, BT30 tool holder

1 unit

eleven

Import; NSK P Grade angle contact paired bearing

6 sets

twelve

Spindle water cooler

1 unit

thirteen

Knife alignment instrument

1 set

fourteen

Electronic pulse handwheel (accuracy of 0.001mm)

1 set

fifteen

X/Y/Z axis with three proof cloth organ cover (Y stainless steel water deflector)

1 set each

sixteen

X/Y/Z axis plastic drag chain

1 set each

seventeen

Automatic lubrication oil pump 2 liters

1 set

eighteen

Gas filter

2 sets

nineteen

Multipoint sprinkler system

1 set

&Nbsp;

twenty

Electric control box constant temperature system

1 set

twenty-one

Vacuum adsorption fixture

4 sets

twenty-two

Cylinder positioning fixture

1 set

twenty-three

Toolbox and machine tool accessories

1 set

twenty-four

Equipped with automatic vacuum drainage system

1 set

&Nbsp< Br/>

4、 Main technical parameters of the equipment:

model

SDSK2818S

External dimensions

Width 4400, length 3800, height 2500

X/Y/Z stroke

2830 * 1830 * 250

Maximum air travel speed

30000mm/min

Maximum processing speed

1200mm/min

control system

Deep carving CNC system

servo system

AC servo

System resolution

zero point zero zero one

Three axis verticality

0.015mm

Whole machine positioning accuracy

0.025mm

Localization accuracy

Precision within 300mm ± 0.01mm

Repetitive positioning accuracy

0.002mm

Spindle power

7.5KW

Knife changing method

Pneumatic

Spindle speed

30000rpm/min

Clamping tool handle

BT30 (maximum 12mm)

Loading height

150mm

The countertop bears a load

500Kg

Rated voltage

380V/50HZ

Maximum power of the entire machine

15KW

Overall weight

14000Kg

&Nbsp< Br/>