This is a newly launched machine with a total of 4 models, 361225152151512.

Machine Introduction:

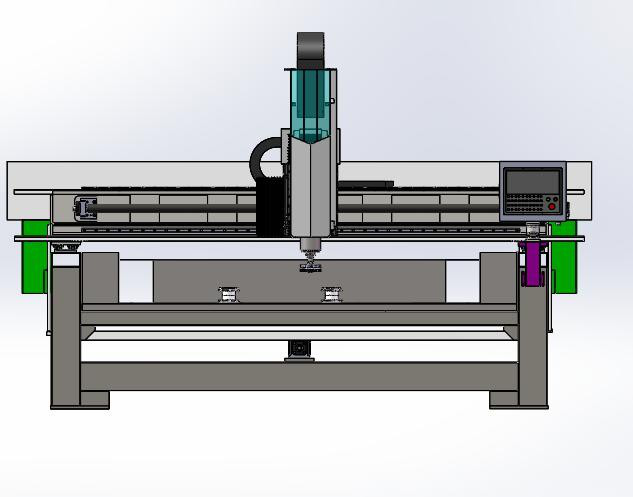

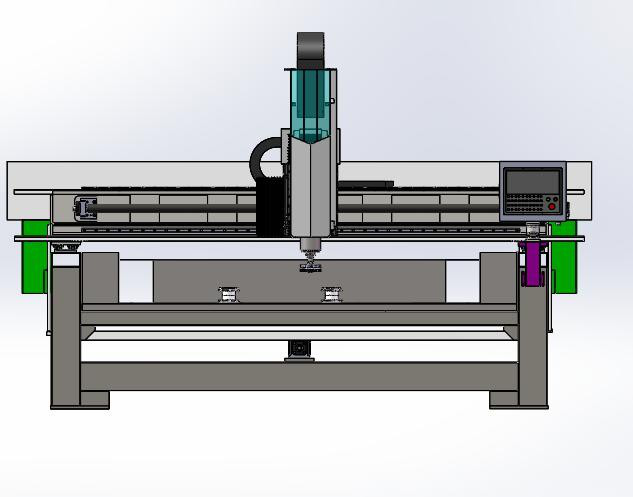

The SDSK3612 model is a CNC large fully functional glass processing machine specially designed for customers; Moving column movement mode; The machine workbench is fixed, the Y-axis gantry moves forward and backward, the entire X-axis head moves left and right, and the Z-axis head moves up and down< Br/>

The body adopts a steel structure, and the three-axis adopts Taiwan Shangyin ball screw, Taiwan Shangyin linear guide rail, German coupling, AC servo motor, advanced spindle cooling system, automatic lubrication system, and water circulation cooling liquid multi-point spray system< Br/>

Ensuring higher machining accuracy, speed, and stability; Specially suitable for precision punching, grinding, chamfering, polishing and other irregular processing of various types of glass cover plates, capacitive screen glass panels, ceramics, etc< Br/>

Number

Specification Description

quantity

one

Machine cover: 2mm steel plate surface powder spraying (stainless steel water tank)

1 set

two

Steel structure bed

1 set

three

Aluminum workbench dimensions: 3600 in X direction, 1200 in Y direction, thickness 25

1 set

four

X. AC servo motor for Y.Z axis (Z with brake)

set

five

Taiwan Shangyin C-grade linear guide rail for XYZ axis

1 set each

six

X. Taiwan Shangyin C5 grade ball screw for Y.Z axis

1 set each

seven

CNC system NC65 (with CCD)

1 set

eight

inverter

1 set

nine

Schneider Electric Accessories

1 batch

ten

Electric spindle 3000-18000 rpm, 18000r/min, diameter 150mm, 8KW (optional 20KW), pneumatic tool change, BT

Knife handle

1 unit

eleven

10 position straight row tool magazine (optional)

nothing

twelve

BT40 knife handle

Two

thirteen

Electronic handwheel

1 unit

fourteen

Spindle water cooler

1 unit

sixteen

NSK P4; Grade angular contact bearing

6 sets

eighteen

Knife alignment instrument

1 set

nineteen

X/Y/Z axis with three proof cloth organ cover

1 set each

twenty

X/Y/Z axis plastic drag chain

1 set each

twenty-one

Automatic lubrication oil pump 2 liters

1 set

twenty-two

water pump

1 set

twenty-four

Jinhuanyu Electric Wire

1 batch

twenty-six

Toolbox and machine tool accessories

1 set

twenty-seven

Control box constant temperature system

1 set

twenty-eight

LED work light alarm system

1 set each

twenty-nine

Multipoint sprinkler system

1 set

thirty

Pneumatic device

3 sets

thirty-one

Glass suction cup

6 sets

Main technical parameters of the equipment:

Model SDSK3612

External dimensions long; 4500 * width; 2300 * High; 2300 (mm)

X/Y/Z; Travel 3620 * 1220 * 300 (mm)

Maximum idle speed 30000mm/min

Maximum processing speed 12000mm/min

Control system deep carving CNC system

Servo system AC servo

System resolution 0.001

Three axis verticality 0.02mm

Positioning accuracy; 0.025mm

Repetitive positioning accuracy of 0.005mm

Number of spindles 1

Spindle power 8KW; (Optional 20KW)

Knife changing method pneumatic

Spindle speed 3000-1800r/min

Clamping tool handle; BT40 maximum; 25mm

Automatic knife alignment method

Can be loaded at a height of 250mm

The countertop can withstand a load of 500Kg

Rated voltage 380V/50Hz

The maximum power of the entire machine is 15KW

Total weight 4500Kg

The triple waterproof technology of waterproof screw and guide rail effectively prevents rust