Technical parameters and configuration table< Br/>

&Nbsp< Br/>

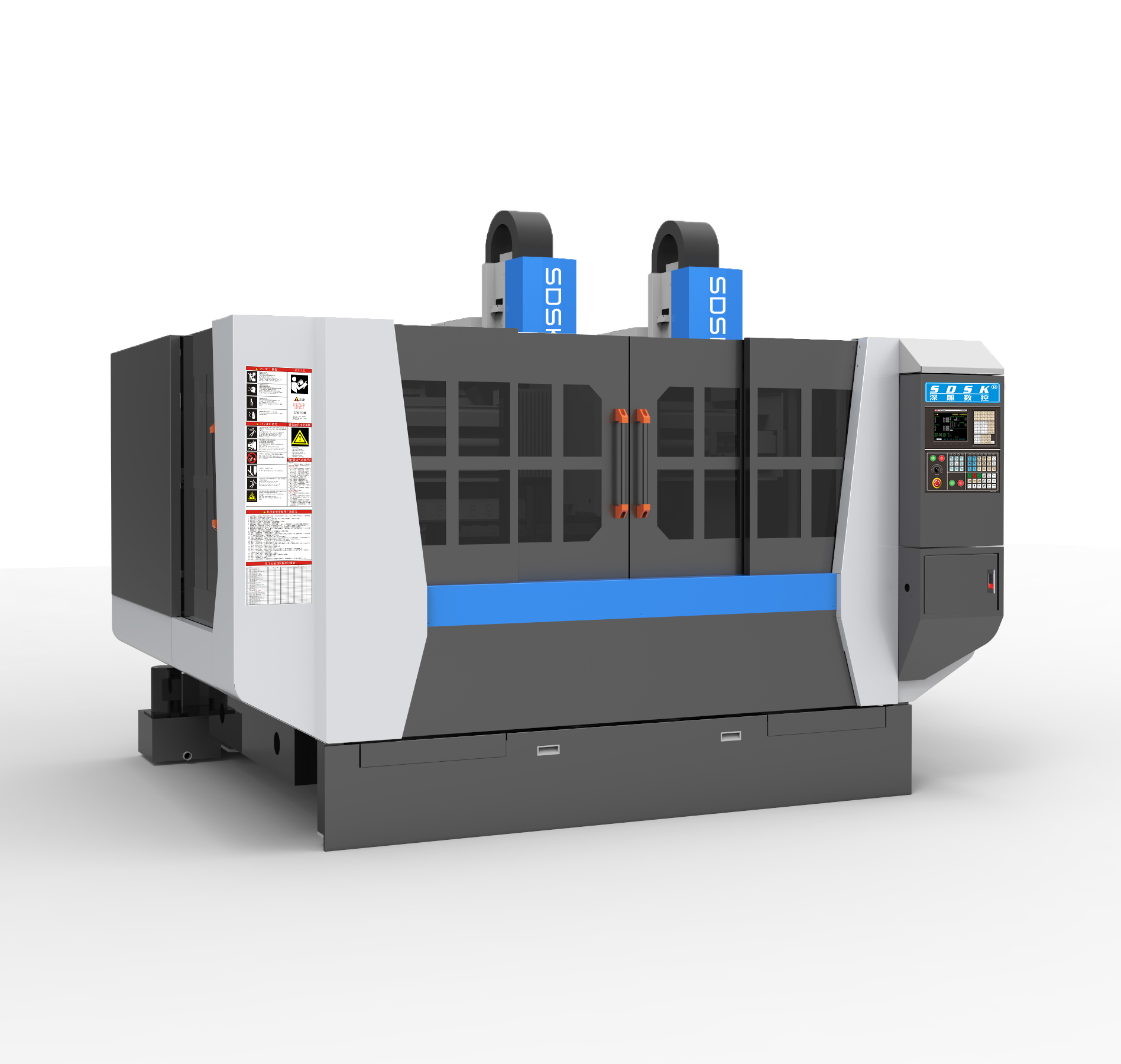

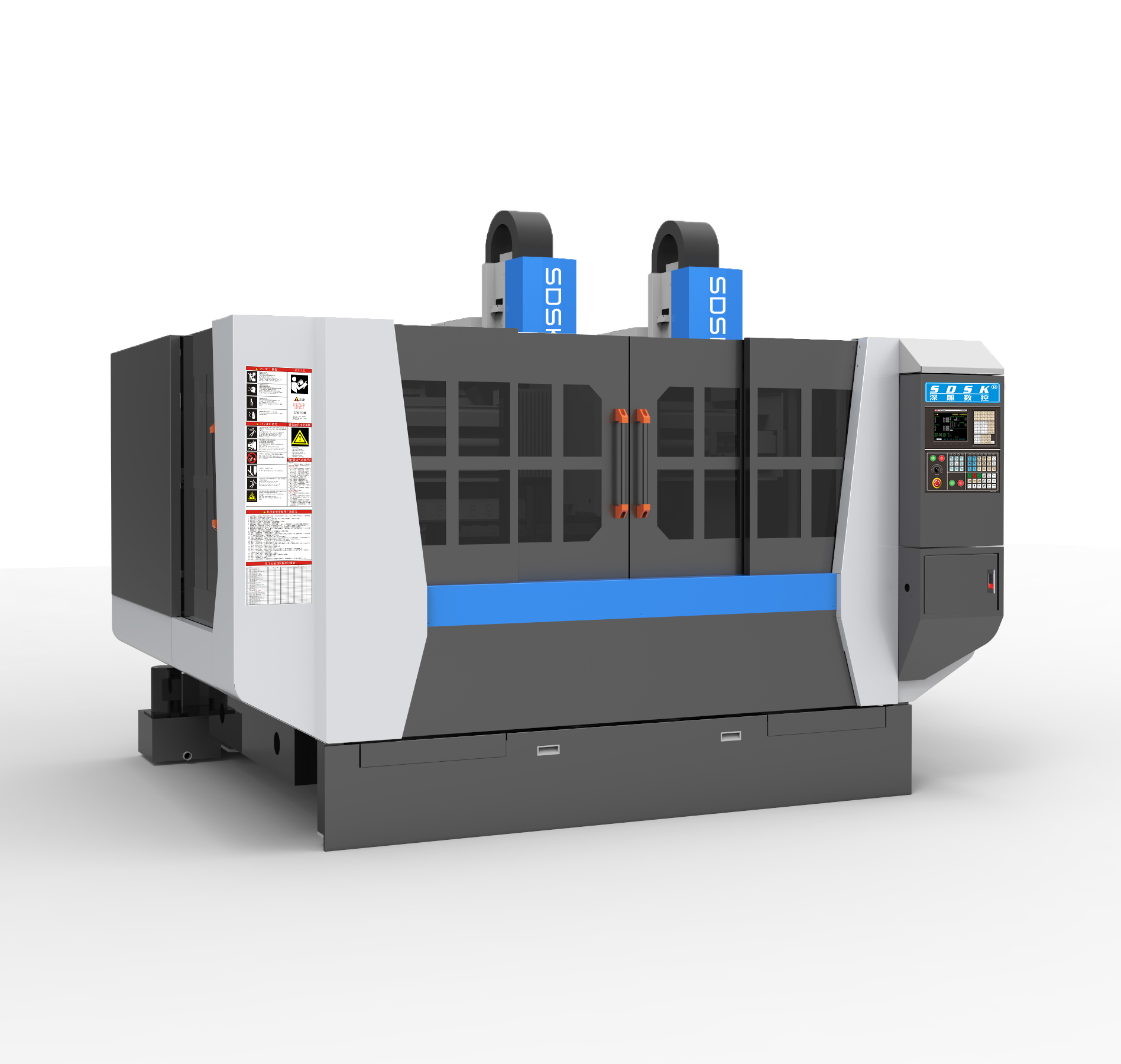

Machine Introduction:

&Nbsp& Nbsp; The SDSK 2Z model is a 2-axis drilling and tapping machine with a tool magazine specially designed for customers; Equipped with a straight blade magazine; There are sliding doors on both the front, back, left, and right sides; The motion mode is to move the Y-axis worktable forward and backward, the X-axis spindle moves left and right, and the 2Z-axis spindle can move up and down simultaneously, drilling and tapping teeth simultaneously, or moving up and down separately. The two spindles clamp the same tool and process it simultaneously, which can greatly improve production efficiency; The body adopts top-notch Jinan granite (marble) structure, which never deforms; Taiwan's complete new generation system/servo motor/spindle drive; The 4-axis adopts imported Taiwan Shangyin/PMI/TBI precision linear guide, precision ball screw, precision coupling, power distribution cabinet thermostatic system, advanced spindle refrigeration system, automatic lubrication system, coolant circulating water spray and spray system, and air filtering device, which ensure higher processing accuracy, speed and stability& Nbsp; Especially suitable for precision 3D carving, milling, precision carving, cutting, drilling, tapping and other processing of various copper, aluminum, acrylic, plastic and other parts< Br/>

Applicable industries: processing of various types of radiators, plumbing equipment, shower sprays, valves, faucets, door and window handles, door locks, electrical case casings, mechanical parts, etc< Br/>

Install a fourth rotating shaft (note: quantity 2)& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp< Br/>

< Br/>

Machine name: 2-head drilling machine with tool magazine

&Nbsp< Br/>

(The picture is for reference only, subject to the actual product, and a full cover may be added)

&Nbsp< Br/>

1、 Main Configuration List of the Machine: (Unit: mm)

Number

Regulations; Grid; Speak; bright

quantity

1.

Outer cover: 2mm steel plate, baked paint (stainless steel water tank)

1 set

2.

Marble body, marble crossbeam

1 set

3.

Used for X/Y/2Z axes; Taiwan Shangyin/PMI& Nbsp; Precision linear guide rail

full set

4.

Used for X/Y/2Z axes; Taiwan TBI/PMI& Nbsp; Precision ball screw

full set

5.

Taiwan's new generation CNC system (21GA/16 axis), new generation servo motor (with driver, 2Z with brake), new generation spindle drive (with encoder)

full set

6.

Schneider Electric Accessories

1 batch

7.

The optional options for the electric spindle parameter table are listed in Table 2

Two

8.

Imported NSK; Precision grade angular contact paired bearings

full set

9.

Spindle water cooler

1 unit

10.

Electronic pulse handwheel (accuracy of 0.001mm)

1 set

11.

X/4Z axis with three proof cloth organ cover, Y-axis steel plate cover

1 set each

12.

X/Y/4Z axis plastic drag chain

1 set each

13.

Knife alignment instrument

1 set

14.

Automatic lubrication oil pump 2 liters

set

15.

Gas filter

1 set

16.

Air water mixing spray, sprinkler

1 set each

17.

Heat exchanger constant temperature system

1 set

18.

Automatic slag removal, placed on the left and right sides below the workbench; (Optional)

2 sets

19.

Knife handle

4

20.

water pump

1 unit

21.

Machine tool accessories

1 set;

2、 The optional options for the electric spindle parameter table are as follows:

Number

Regulations; Grid; Speak; bright

quantity

&Nbsp;

The optional options for the electric spindle parameter table are as follows:

1、 Spindle distance: 350mm, workbench size 700 * 600

1. Electric spindle 30000 revolutions per minute/4.6KW/outer diameter 110mm/pneumatic tool change/with encoder/equipped with BT30 tool holder/can be equipped with a straight row tool library of 2 * 4 positions< Br/>

2. Electric spindle 40000 rpm/3.0KW/outer diameter 80mm/pneumatic tool change/with encoder/ Equipped with ISO20 tool holder/can be equipped with a straight row tool magazine with 2 * 6 positions< Br/>

3. Electric spindle 60000 revolutions per minute/2.5KW/outer diameter 62mm/pneumatic tool change/with encoder/equipped with ISO10 tool holder/can be equipped with a straight row tool library of 2 * 9 positions< Br/>

2、 Spindle distance: 500mm, workbench size 1000 * 600

1. Electric spindle 30000 revolutions per minute/4.6KW/outer diameter 110mm/pneumatic tool change/with encoder/equipped with BT30 tool holder/can be equipped with a straight row tool library of 2 * 6 positions< Br/>

2. Electric spindle 40000 rpm/3.0KW/outer diameter 80mm/pneumatic tool change/with encoder/ Equipped with ISO20 tool holder/can be equipped with a straight row tool library of 2 * 8 positions< Br/>

3. Electric spindle 60000 revolutions per minute/2.5KW/outer diameter 62mm/pneumatic tool change/with encoder/equipped with ISO10 tool holder/can be equipped with a straight row tool library of 2 * 13 positions< Br/>

3、 Spindle distance: 700mm, workbench size 1400 * 500

1. Electric spindle 30000 revolutions per minute/4.6KW/outer diameter 110mm/pneumatic tool change/with encoder/equipped with BT30 tool holder/can be equipped with a straight row tool library of 2 * 8 positions< Br/>

2. Electric spindle 40000 rpm/3.0KW/outer diameter 80mm/pneumatic tool change/with encoder/ Equipped with ISO20 tool holder/can be equipped with 2 * 12 positions of straight row tool magazine< Br/>

3. Electric spindle 60000 revolutions per minute/2. 5KW/outer diameter 62mm/pneumatic tool change/with encoder/equipped with ISO10 tool holder/can be equipped with a straight row tool library of 2 * 18 positions< Br/>

4、 Spindle distance: 750mm, workbench size 1500 * 600

1. Electric spindle 30000 revolutions per minute/4.6KW/outer diameter 110mm/pneumatic tool change/with encoder/equipped with BT30 tool holder/can be equipped with a straight row tool library of 2 * 9 positions< Br/>

2. Electric spindle 40000 rpm/3.0KW/outer diameter 80mm/pneumatic tool change/with encoder/ Equipped with ISO20 tool holder/can be equipped with 2 * 13 positions for straight row tool magazine< Br/>

3. Electric spindle 60000 revolutions per minute/2.5KW/outer diameter 62mm/pneumatic tool change/with encoder/equipped with ISO10 tool holder/can be equipped with a straight row tool library of 2 * 18 positions< Br/>

5、 Spindle distance: 850mm, workbench size 1700 * 800

1. Electric spindle 30000 revolutions per minute/4.6KW/outer diameter 110mm/pneumatic tool change/with encoder/equipped with BT30 tool holder/can be equipped with a straight row tool magazine of 2 * 10 positions< Br/>

2. Electric spindle 40000 rpm/3.0KW/outer diameter 80mm/pneumatic tool change/with encoder/ Equipped with ISO20 tool holder/can be equipped with a 2 * 15 position straight row tool library< Br/>

3. Electric spindle 60000 revolutions per minute/2.5KW/outer diameter 62mm/pneumatic tool change/with encoder/equipped with ISO10 tool holder/can be equipped with a straight row tool library of 2 * 20 positions< Br/>

6、 Spindle distance: 1000mm, workbench size 2000 * 800

1. Electric spindle 30000 revolutions per minute/4.6KW/outer diameter 110mm/pneumatic tool change/with encoder/equipped with BT30 tool holder/can be equipped with 2 * 12 positions of straight row tool magazine< Br/>

2. Electric spindle 40000 rpm/3.0KW/outer diameter 80mm/pneumatic tool change/with encoder/ Equipped with ISO20 tool holder/can be equipped with a straight row tool library of 2 * 18 positions< Br/>

3. Electric spindle 60000 revolutions per minute/2.5KW/outer diameter 62mm/pneumatic tool change/with encoder/equipped with ISO10 tool holder/can be equipped with a straight row tool library of 2 * 20 positions< Br/>

7、 Spindle distance: 1250mm, workbench size 2500 * 800

1. Electric spindle 30000 revolutions per minute/4.6KW/outer diameter 110mm/pneumatic tool change/with encoder/equipped with BT30 tool holder/can be equipped with a straight row tool magazine of 2 * 15 positions< Br/>

2. Electric spindle 40000 rpm/3.0KW/outer diameter 80mm/pneumatic tool change/with encoder/ Equipped with ISO20 tool holder/can be equipped with 2 * 20 positions of straight row tool magazine< Br/>

3. Electric spindle 60000 revolutions per minute/2.5KW/outer diameter 62mm/pneumatic tool change/with encoder/equipped with ISO10 tool holder/can be equipped with a straight row tool library of 2 * 20 positions.

&Nbsp< Br/>

&Nbsp< Br/>

Two

3、 Main technical parameters of the equipment: (unit: mm)

model

SDSK350-2Z

SDSK500-2Z

SDSK700-2Z

SDSK750-2Z

SDSK850-2Z

SDSK1000-2Z

SDSK1250-2Z

External dimensions

2300 in length, 2300 in width, and 2500 in height

2300 in length, 2300 in width, and 2500 in height

2630 in length, 2130 in width, and 2300 in height

2750 in length, 2330 in width, and 2300 in height

3100 in length, 2600 in width, and 2700 in height

3400 in length, 2600 in width, and 2700 in height

3900 in length, 2600 in width, and 2700 in height

Aluminum workbench dimensions

1000 * 600 * 50 (with T-groove)

1000 * 600 * 50 (with T-groove)

1400 * 500 * 50 (with T-groove)

1500 * 600 * 50 (with T-groove)

1700 * 800 * 50 (with T-groove)

2000 * 800 * 50 (with T-groove)

2500 * 800 * 50 (with T-groove)

X/Y/Z stroke

500 * 630 * 350

650 * 630 * 350

850 * 530 * 300

900 * 630 * 300

1000 * 830 * 350

1150 * 830 * 350

1400 * 830 * 350

Maximum air travel speed

30000mm/min

30000mm/min

30000mm/min

30000mm/min

30000mm/min

30000mm/min

30000mm/min

Maximum processing speed

12000mm/min

12000mm/min

12000mm/min

12000mm/min

12000mm/min

12000mm/min

12000mm/min

control system

Taiwan's new generation CNC system

Taiwan's new generation CNC system

Taiwan's new generation CNC system

Taiwan's new generation CNC system

Taiwan's new generation CNC system

Taiwan's new generation CNC system

Taiwan's new generation CNC system

servo system

AC servo

AC servo

AC servo

AC servo

AC servo

AC servo

AC servo

System resolution

zero point zero zero one

zero point zero zero one

zero point zero zero one

zero point zero zero one

zero point zero zero one

zero point zero zero one

zero point zero zero one

Three axis verticality

0.015mm

0.015mm

0.015mm

0.015mm

0.015mm

0.015mm

0.015mm

Whole machine positioning accuracy

0.015mm

0.015mm

0.015mm

0.015mm

0.015mm

0.015mm

0.015mm

Localization accuracy

Precision within 300mm ± 0.01mm

Precision within 300mm ± 0.01mm

Precision within 300mm ± 0.01mm

Precision within 300mm ± 0.01mm

Precision within 300mm ± 0.01mm

Precision within 300mm ± 0.01mm

Precision within 300mm ± 0.01mm

Repetitive positioning accuracy

0.005mm

0.005mm

0.005mm

0.005mm

0.005mm

0.005mm

0. 005mm

Number of spindles

Two& Nbsp; (Main spindle distance 350mm)

Two& Nbsp; (Spindle distance 500mm)

Two& Nbsp; (Main spindle distance 700mm)

Two; (Main spindle distance 750mm)

Two; (Main spindle distance 850mm)

Two; (Spindle distance 1000mm)

Two; (Spindle distance 1250mm)

Electric spindle power

4.6KW/piece

(Optional for reference parameters)

4.6KW/piece

(Optional for reference parameters)

4.6KW/piece

(Optional for reference parameters)

4.6KW/piece< Br/>

(Optional for reference parameters)

4.6KW/piece

(Optional for reference parameters)

4.6KW/piece

(Optional for reference parameters)

four. 6KW/piece

(Optional for reference parameters)

Straight row tool magazine

2 * 4 digits

2 * 6 digits

2 * 8 digits

2 * 9 digits

2 * 10 digits

2 * 12 digits

2 * 15 digits

Knife changing method

automatic

automatic

automatic

automatic

automatic

automatic

automatic

Spindle speed

30000rpm/min

30000rpm/min

30000rpm/min

30000rpm/min

30000rpm/min

30000rpm/min

30000rpm/min

Clamping tool handle

BT30 (maximum 12mm)

BT30 (maximum 12mm)

BT30 (maximum 12mm)

BT30 (maximum 12mm)

BT30 (maximum 12mm)

BT30 (maximum 12mm)

BT30 (maximum 12mm)

Knife alignment method

automatic

automatic

automatic

automatic

automatic

automatic

automatic

Loading height

250mm

250mm

250mm

250mm

250mm

250mm

250mm

The countertop bears a load

500Kg

500Kg

500Kg

500Kg

500Kg

500Kg

500Kg

Rated voltage

380V/50HZ

380V/50HZ

380V/50HZ

380V/50HZ

380V/50HZ

380V/50HZ

380V/50HZ

Maximum power of the entire machine

14KW

14KW

14KW

14KW

15KW

15KW

15KW

Overall weight

2000Kg

4000Kg

3200Kg

4200Kg

5800Kg

6200Kg

7000Kg

< Br/>

< Br/>