Aluminum profile extrusion is one of the important processes in aluminum profile processing, and the manufacturing of aluminum profile extrusion process molds is directly related to the quality and service life of aluminum extruded profiles

Aluminum profile extrusion is one of the important processes in aluminum profile processing. The manufacturing of aluminum extrusion process molds directly affects the quality and service life of aluminum extruded profiles. Because aluminum extrusion process molds have a series of characteristics, aluminum profile mold making technology needs to meet some special requirements:

Firstly, the working conditions of aluminum alloy extrusion process molds are extremely harsh. During the extrusion process, they need to withstand high temperature, high pressure, and high friction. Therefore, the material of the mold needs to use high-strength and heat-resistant alloy steel. The process of melting, casting, forging, heat treatment, electrical processing, mechanical processing, and surface treatment of these steel materials is relatively complex, which adds a lot of difficulties to mold manufacturing and processing< Br/>

Secondly, in order to improve the service life of molds and ensure the surface quality of aluminum profiles, it is necessary to require the roughness of the working strip in the mold cavity to reach 0.8-0.4μ m. And the roughness of the mold plane reaches 1.6μ Therefore, special polishing processes and polishing machinery, as well as high-precision processing equipment, such as slow threading equipment, need to be adopted during mold making< Br/>

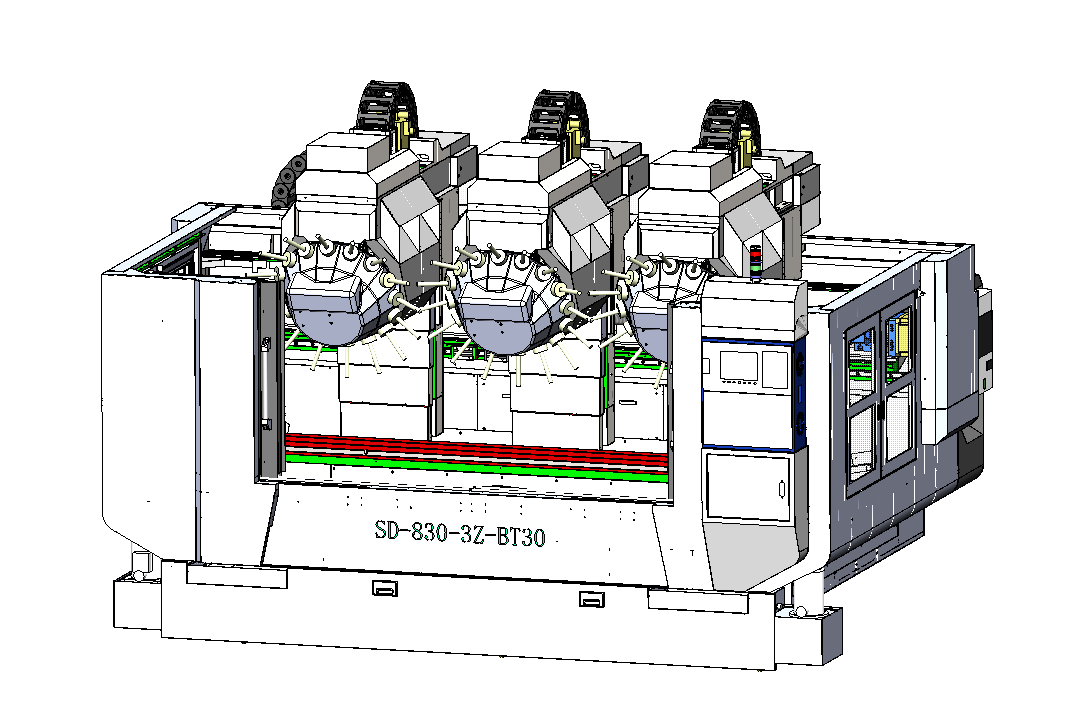

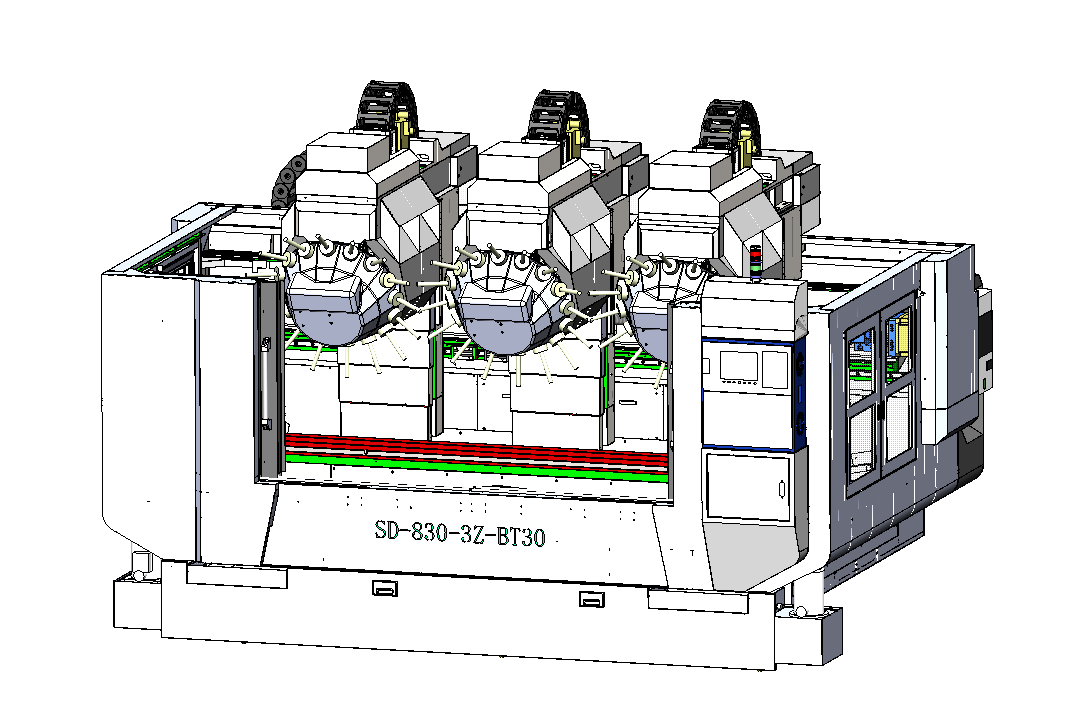

Thirdly, currently, customers have increasingly high requirements for aluminum extrusion products, gradually moving towards a trend of high, precision, and sharpness. Some profiles and pipes have a wall thickness requirement reduced to around 0.5mm, and their extruded products have a tolerance requirement of± 0.05mm, in order to extrude this ultra-high precision product, the manufacturing accuracy of the mold is required to reach 0.01mm, which cannot be produced by traditional processes. Therefore, it is required to update the process and use new specialized equipment, such as CNC machining centers< Br/>

Fourthly, the cross-section of aluminum profiles is very complex, especially for ultra-high precision thin-walled hollow aluminum profiles and porous hollow wall panel aluminum profiles, which require the use of special extrusion mold structures. Often, multiple irregular cavities are opened on a single mold at the same time, and the thickness of each cross-section changes sharply. The related dimensions are complex, and there are many arc corners, which brings a lot of trouble to the processing and heat treatment of the mold< Br/>

Fifthly, there are a wide variety of aluminum profile extrusion products with small batches and frequent mold changes, which require strong adaptability of the mold. Therefore, it is necessary to improve the production efficiency of the mold, shorten the mold making cycle as much as possible, quickly change the mold making program, accurately and accurately process qualified molds according to the drawings, and reduce the workload of mold repair to the minimum< Br/>

Sixth, nowadays, the application range of aluminum alloy extrusion products is becoming increasingly widespread, with a very wide range of specifications. Therefore, there are external dimensions as small as several kilograms, with a size of 100mm× A 25mm small mold with an external dimension of 1800mm and times, weighing over 2000kg; 450mm large mold. The external dimensions are as light as a few thousand grams and are 65mm× 800mm small extrusion shaft, also weighing over 100t, with an external dimension of 2500