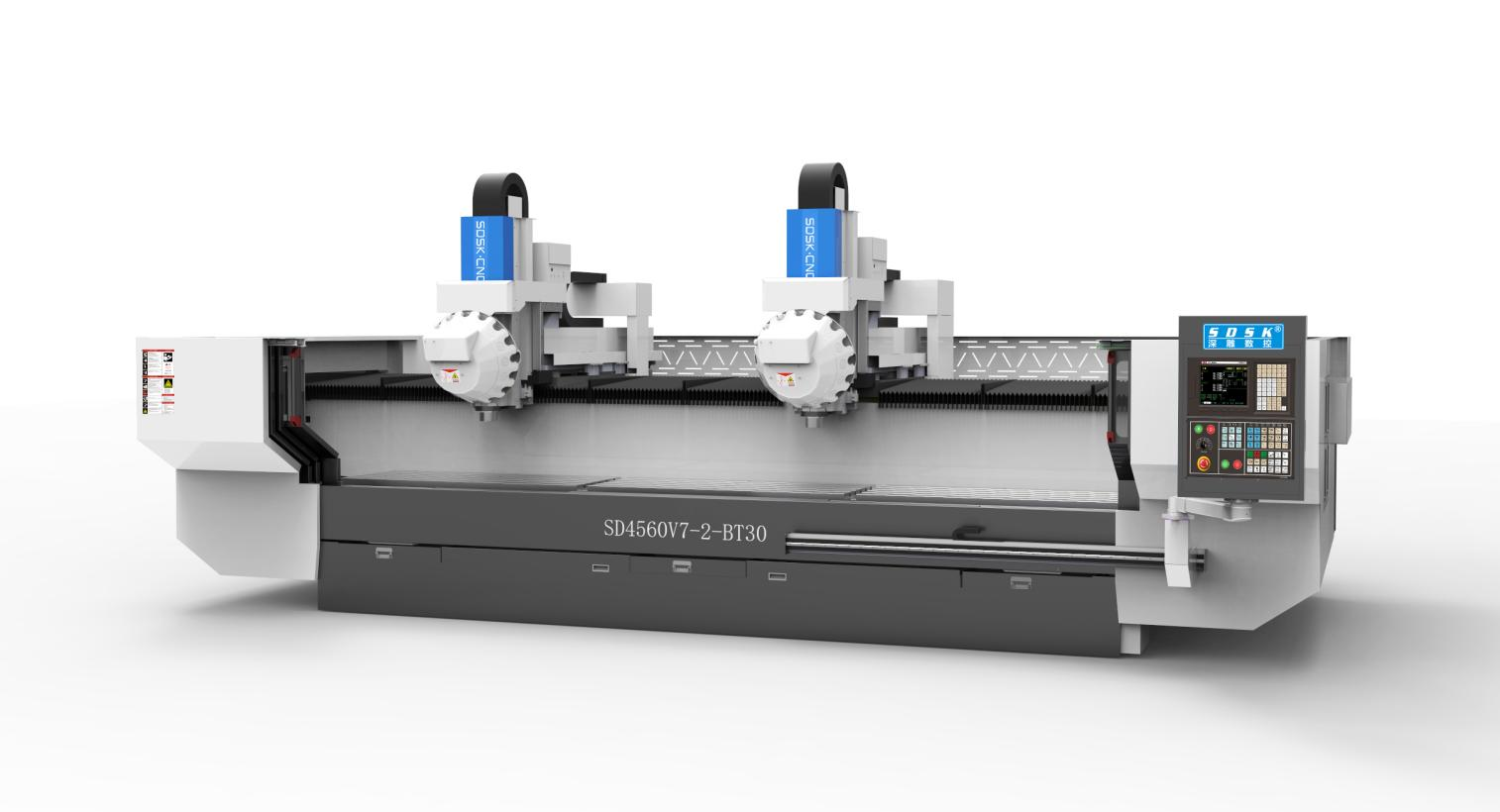

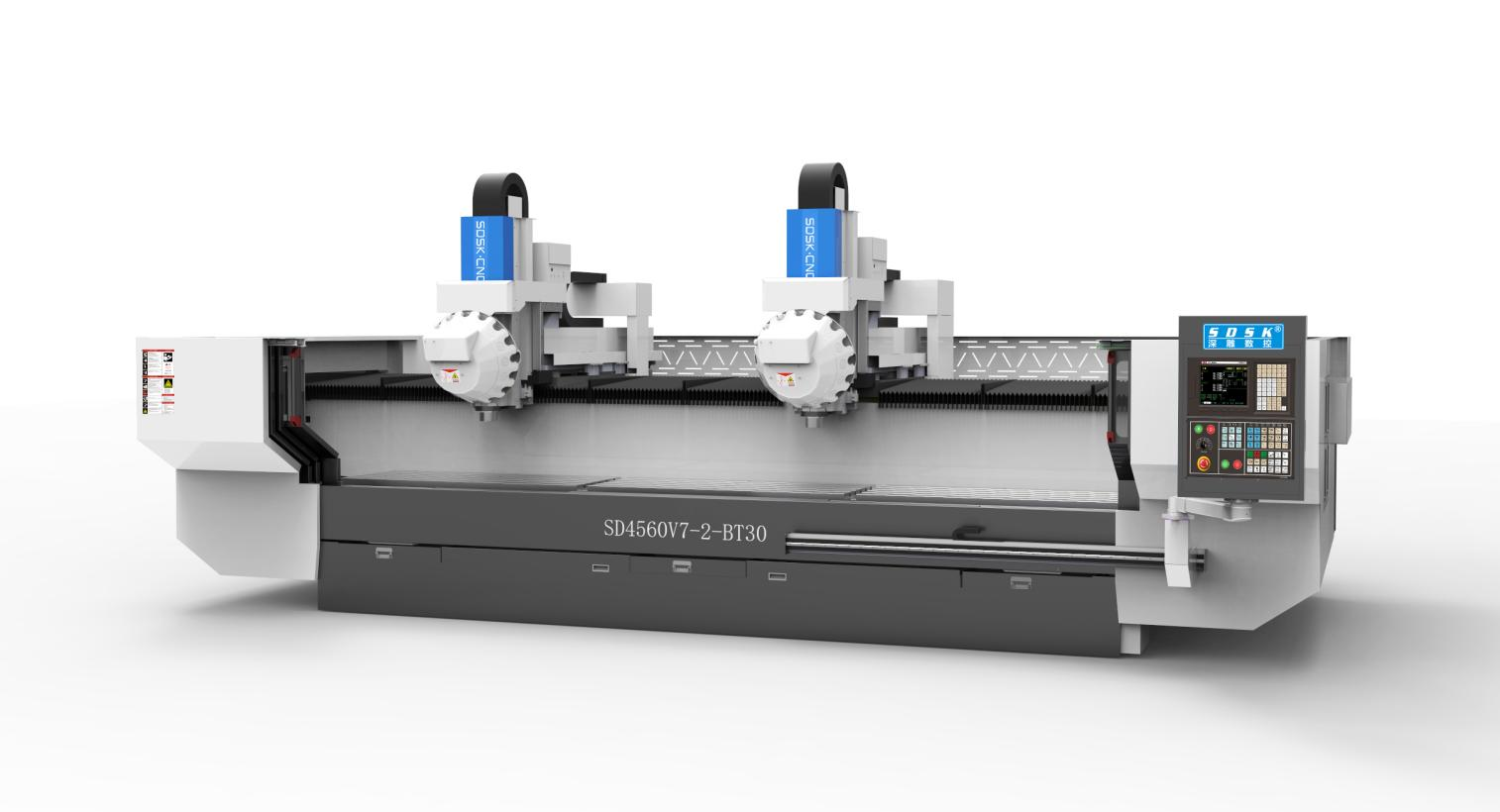

Shenzhen Jingdiao CNC CNC Aluminum Profile Processing Center is a CNC equipment that integrates milling, drilling, boring, tapping, cutting, chamfering, and 3D surface processing. It is suitable for processing various lengths of steel, copper, aluminum, and other metals

Shenzhen Jingdiao CNC Aluminum Profile Processing Center is a CNC equipment that integrates milling, drilling, boring, tapping, cutting, chamfering, and 3D surface processing. It is suitable for processing various lengths of steel, copper, aluminum, and other metals

In the mold processing plant, the CNC machining management center is mainly used for processing key mold components such as mold cores and inserts, as well as copper pins. The quality of the mold core and inserts immediately determines the quality of a part of the mold forming. The quality of copper processing immediately controls the hazards of EDM processing. To ensure the quality of CNC machining, it is necessary to prepare in advance before machining. For this position, in addition to having rich and diverse machining work experience and mold knowledge, it is also important to pay attention to excellent communication and exchange in work, especially with production personnel and friends< Br/>

CNC machining center operation experience (1) CNC machining steps

1) Read articles on engineering drawings and program sheets

2) Transfer the corresponding program to the CNC lathe

3) Verify program header, drilling main parameters, etc.

4) Clarification of processing specifications and capacity in the process flow on the workpiece

5) Effective clamping of workpieces

6) Accurate alignment of workpieces

7) Accurate creation of workpiece coordinates

8) Selection of effective cutting tools and main parameters for drilling

9) Effective clamping of cutting tools

10) Tool radius compensation method for safety

11) Observation of the entire processing process

12) Adjusting the main parameters of drilling

13) Difficulties throughout the entire processing and timely feedback from corresponding staff

14) Inspection of workpiece quality after processing

Common problems before processing

1) For new molds, the machining drawings must comply with regulations and the data information must be clear; The machining drawing of the new mold needs to be signed by the person in charge, and all columns of the machining drawing have been filled in< Br/>

2) The workpiece has a compliance mark from the quality department< Br/>

3) After receiving the program order, check if the standard position of the workpiece is consistent with the standard position on the engineering drawing< Br/>

4) Understand each provision in the program sheet, determine if the program is consistent with the specifications on the engineering drawings, and if there are any issues, be sure to work with the programmer and production personnel to solve the difficulties< Br/>

5) Based on the raw materials and dimensions of the workpiece, the resolution range