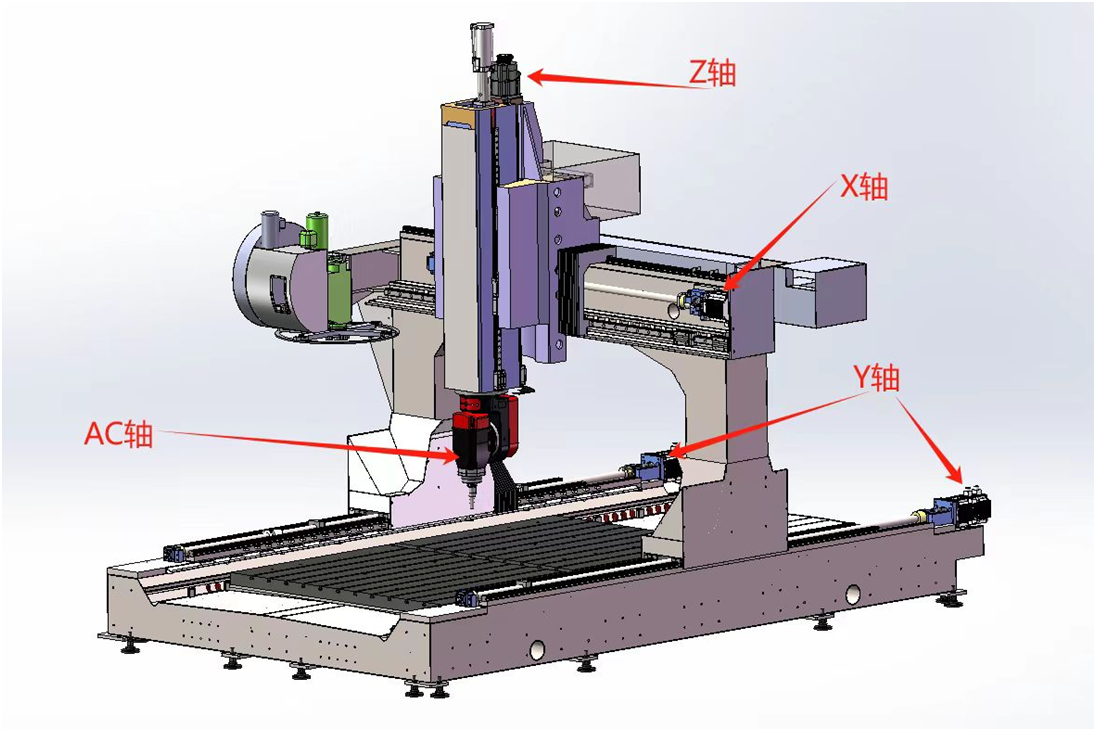

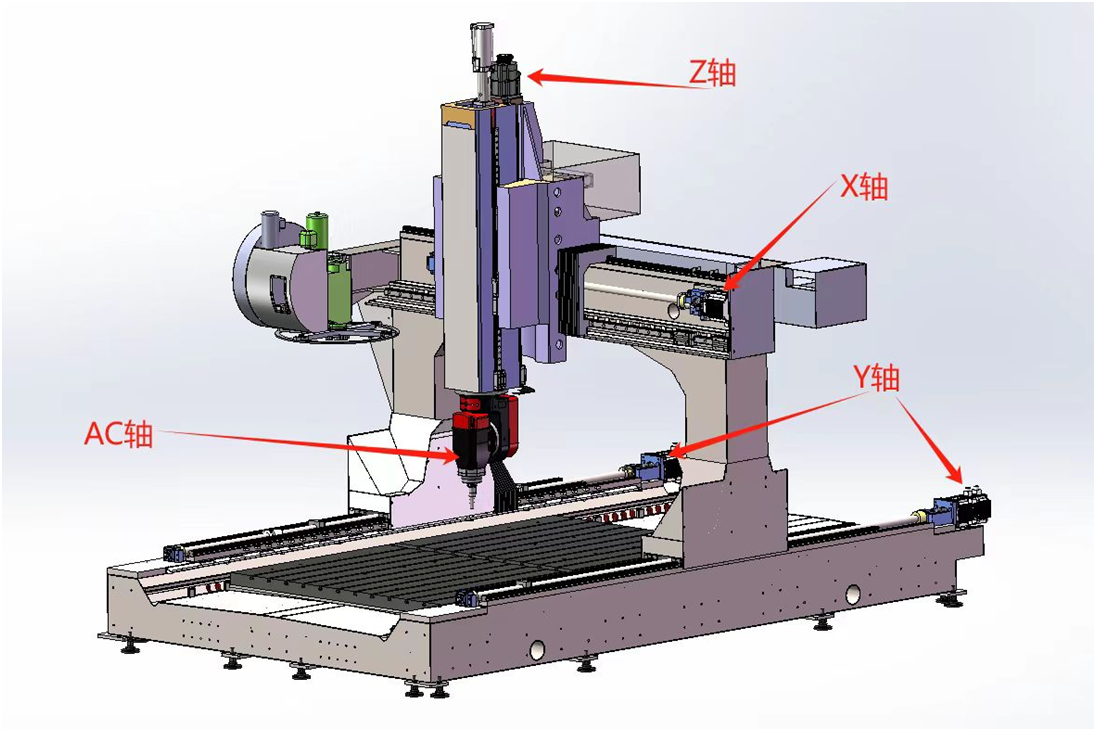

Machine Introduction:

SDSK3020WDL-BT40 is a 4-meter moving beam AC five axis gantry machining center specially designed for customers, with a fixed workbench.

The motion mode is forward and backward movement of the Y-axis gantry, left and right movement of the X-axis machine head, up and down movement of the Z-axis spindle, and the A-axis can± 110· Rotation, C-axis can± 360· Rotate.

Equipped with RTCP tool tip following function, it can complete five axis linkage machining;

Especially suitable for precision 3D engraving, side milling, end milling, cutting, drilling, tapping and other processing of various types of steel, copper, aluminum, acrylic, plastic and other parts.

(The pictures are for reference only, subject to the actual product)

2、 List of Main Machine Configuration (Unit: mm)

Regulations; Grid; Speak; bright

quantity

Origin

New generation system (22MA)/spindle servo drive 15-18000, with RTCP tool tip following function (optional)

full set

Taiwan

X-axis 6.9KW servo motor (new generation)

1 set

Taiwan

Y-axis 6.9KW servo motor (new generation)

2 sets

Taiwan

Z-axis 3.9KW servo motor with band brake (new generation)

1 set

Taiwan

Y-axis reducer, (or equivalent brand)

2 sets

Taiwan

AC axis swing head (with additional technical instructions)< Br/>

Including Big Joy Electric Spindle BT40-150-545-18000, 15KW, pneumatic tool change, with encoder;

1 set

Taiwan

Use Taiwan Shangyin/Intime for XYZ axis; Precision grade ball linear guide (X45-2, Y45-4, Z35-4), (or equivalent brand)

full set

Taiwan

Taiwan TBI for XZ axis; Precision grinding grade ball screw (XY50, Z40), (or equivalent brand)

1 set each

Taiwan

Equipped with a 24 position disc cutter magazine (Okada)

1 set

Taiwan

Steel composite bed body, mainly consisting of cast iron mechanical parts (HT300)

1 set

self-control

Distribution cabinet air conditioning constant temperature system (Reid)

1 set

Dongguan

Schneider Electrical Accessories (Schneider)

1 batch

Germany

Importing NSK/KOYO from Japan; P-grade angular contact paired bearings, (or equivalent brand)

full set

Japan

Spindle oil cooler (Red), (or equivalent brand)

1 unit

Dongguan

Electronic handwheel (Shenzhen Jingdiao)

1 set

self-control

Knife setting instrument (Shenzhen Jingdiao)

1 unit

self-control

XYZ axis with three proof cloth organ cover

1 set each

self-control

X/Y/Z axis plastic drag chain (Dingtai)

1 set each

Dongguan

Automatic lubrication oil pump (Proton)

1 set

Dongguan

Air filter (Japanese Lehman M107-A air filter)

1 set

Zhejiang

Water spray device

1 set

self-control

Water pump 750W (Snell), (or equivalent brand)

1 set

Changzhou

Air gun, water gun

1 each

Zhejiang

Machine tool accessories

1 set

Shenzhen

Knife handle/complete set of reducing nipples (three in one)

5

Shenzhen

Double screw+chain plate automatic slag discharge machine

1 set

self-control

Automatic double door (optional)

nothing

self-control

3、 Technical specification parameter table: (unit: mm)

model

SDSK3020WDL-BT40

Workbench size

X2000 * Y3000; (T-slot M16)

Dimensions from workbench to ground

Around 480

Gantry width

two thousand and three hundred

Spindle nose end to workbench

Maximum 700 to minimum 150

A-axis rotation angle 0· Time X-axis travel

two thousand

A-axis rotation angle 0· Time Y-axis travel

three thousand

Z-axis travel

seven hundred

A-axis rotation angle

&Plusmn; 110·

C-axis rotation angle

&Plusmn; 360·

A-axis± 90· Distance between the nose ends of the two main axes

X: 1230

Y: 2430

X/Y/Z fastest movement speed

X48 meters per minute

Y28 meters/minute

Z48 meters/minute

Maximum processing speed

12 meters per minute

servo system

AC servo

System resolution

zero point zero zero one

Three axis verticality

0.015mm

Whole machine positioning accuracy

&Plusmn; 0.05mm

Localization accuracy

Within 300± 0.01mm

Repetitive positioning accuracy

0.005mm

Number of spindles

1

Spindle power

15KW

Spindle torque

34.5N. m

Spindle speed

18000rpm/min

Disc type tool magazine

24 bit

Maximum tool length

200mm

Maximum tool diameter

80mm

Knife changing method

automatic

Clamping tool handle

BT40

Knife alignment method

automatic

The countertop bears a load

3000Kg

Rated voltage

380V/50HZ

Maximum power of the entire machine

About 45KW

Overall weight

About 18000kg

External dimensions (length * width * height)

Around 4300 * 7200 * 3800

5、 AC swing head parameter description:

Number

name

model

parameter

one

C-axis harmonic reducer

RD-100C

Speed ratio 11:1

two

A-axis gear indexing plate

250YB

Speed ratio 1:30

three

C-axis working range

&Nbsp;

&Plusmn; 360°

four

A-axis working range

&Nbsp;

&Plusmn; 115°

five

A-axis/rated maximum torque

&Nbsp;

1320Nm

six

C-axis/rated maximum torque

&Nbsp;

4900Nm

seven

A/C-axis servo motor power

1.8KW/1.8KW

&Nbsp;

eight

A/C axis accuracy

&Nbsp;

&Plusmn; 10 (SEC)/± 10 (SEC)

nine

Electric spindle power/torque

BT40-150-545-1800rpm

15KW/34.5Nm

ten

Knife cutting method

Pneumatic

Air pressure; 0.6 MPa

eleven

Total weight

&Nbsp;

About 90kg

5、 Standard configuration and accessories for the host:

one

Controller

eleven

1 mechanical, electrical, and operation manual

two

AC Swinging Head Assembly

twelve

Rigid tapping function

three

Automatic lubrication system

thirteen

Electrical box air conditioning

four

Adjustable foundation cushion block

fourteen

Operation Manual, Program Manual, and User Manual

five

Toolbox

fifteen

5 knife handles (including rivets and wrenches)

six

Work lights

sixteen

Lock blade holder

seven

Warning lights

seventeen

&Nbsp; M16 Ma Tie

eight

Spindle blowing device

eighteen

One 6-inch screwdriver

nine

transmission line

nineteen

Lock Mouth; ER25 (4-12) 1 set

ten

Semi enclosed cover

twenty

Shield

6、 Machine environment and hardware facility requirements;

Number

Environmental projects

Project Requirements Standards

one

Power requirements

AC380V (4P) 50-60Hz, air switch 100A, power supply voltage fluctuation range 380V± Within 10%

two

air compressor

Using screw compressor, air storage tank, three-stage filtration,≥ 0.55Mpa, flow rate≥ 100L/min

three

Vacuum pressure

&Ge; 0.6 MPa

four

Air dryer

Must have an air dryer with automatic drainage function

five

Environmental noise/vibration

&Le; 75dba

six

Ground requirements

The ground is required to be flat, stable, and the difference between the highest and lowest points should not exceed 5mm

seven

Environmental humidity

Suggest 45% -65%

eight

Gas moisture content

No moisture

Shenzhen Jingdiao CNC Equipment Co., Ltd

Address: Buildings 29, 30, and 31, Third Industrial Zone, Xitian Community, Gongming Street, Guangming District, Shenzhen

Telephone: 0755-29423909, 0755-29588251

Mobile phone: 13924586646 Mr. Zhou (same WeChat account)

Tiktok number: SDSK20211688

Email: sz_jdsk@163.com

Company website: www.cncjdj. com

Official website of Aluminum Profile Processing Center: www.szjdsk. cn

New Energy Vehicle Parts Network: www.sdskcnc. cn

&Nbsp;